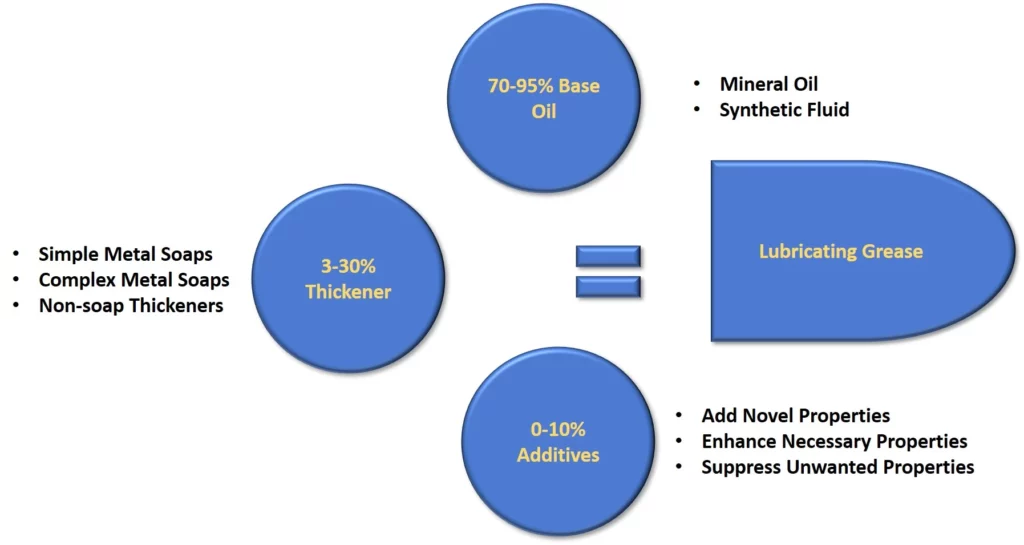

Grease lubricant is formed by dispersing a thickening agent in a liquid lubricant to produce a solid to semi-fluid product.

The composition of grease lubricant is composed of three components. In addition to base oil and thickener, additives are also present in the composition of grease lubricant.

Lubricant formulations primarily include base oils and additive packages. The lubricant (base oil plus additives) is held in place by the thickener.

Article Navigation

Base Oil

Mineral oil is the main fluid component of most greases produced today. Most industrial applications can be satisfied with these mineral oil-based grease lubricants. Synthetic base oils provide better stability at extreme temperatures (low or high).

Thickener

Solid to semifluid transition is achieved by using the thickener in conjunction with the selected lubricant. Currently, metallic soap is the most common thickener used in grease. The materials used in these models include lithium, aluminum, clay, polyurea, sodium, and calcium, among others.

There has been an increase in the popularity of complex thickener-type greases in recent years. There is an excellent load-carrying ability and high dropping points that make them suitable for use in this application.

Additives

When it comes to grease lubricants, additives can play a variety of roles. They are primarily concerned with increasing the quality of the existing desirable properties, suppressing the quality of the existing undesirable properties, or conferring new qualities.

Additives are commonly used to protect from oxidation and rust, exert extreme pressure to reduce wear and friction, and prevent corrosion as well.

The functionality of Grease Lubricant

Despite gravity, centrifugal force, or pressure, grease lubricant remains in contact with moving surfaces and lubricates them without leaking out. It must retain its properties under shear forces At all temperatures during use.

What Grease Is Good For

- The purpose of grease is to seal the joints and keep contaminants out, minimizing leakage.

- Grease lubricant consistency prevents leakage and stops foreign materials and harmful contaminants from entering. In addition, it maintains the effectiveness of deteriorated seals.

- Oil cannot be contained as easily as grease lubricant. Circulating oil and complex retention devices can be expensive in oil lubrication. Compared with grease lubricant, which is rigid, simpler, and less costly retention devices are easily able to confine it.

- The solid lubricants are suspended in the grease. In high-temperature applications or out at extreme pressures, finely ground solid lubricants are mixed with grease. Such lubricants include molybdenum disulfide and graphite. Solids settle out of oils while grease holds them in suspension.

- Monitoring and controlling fluid levels are not necessary.

Related Article: Classification of Lubricants with their Names (2022)? [Explained]

Characteristics of Grease Lubricant

Products datasheets typically list the following characteristics:

Pumpability

The ability to pump or push grease lubricant through a system can be described as pumpability. Pumpability is more practical in its meaning as it describes the ease with which a pressurized grease lubricant can be dispensed through nozzles, fittings, and lines of grease dispensing systems.

Adaptability to water

Grease lubricant is able to withstand the effects of water without losing its lubricating ability. In soap/water lathers, the oil can be suspended, making an emulsion, which washes away or, to a lesser extent, dilute and change the consistency of grease.

Stability

Thickener type and amount, as well as oil viscosity, determine the consistency of grease lubricant. An applied force can deform grease’s consistency if it is applied too forcefully.

Consistency can be measured by penetration. The ability to penetrate depends on the consistency and whether it has been altered by handling or working. Methods ASTM D 217 and D 1403 are used to measure grease penetration.

At a standard temperature of 25°C, a cone is allowed to sink for five seconds into grease in order to measure penetration.

The dropping point

The heat resistance of grease is measured by its dropping point. The penetration of grease increases with increasing grease temperature until the desired consistency is lost as the grease liquefies.

Grease becomes liquid when it reaches the dropping point. In contrast to the maximum temperature at which grease can be used, the dropping point indicates the highest temperature at which the grease can retain its structure.

Reliability to oxidation

There is a characteristic of grease that allows it to resist the forming of a chemical bond with oxygen. Grease is converted into sludges, sludge-like deposits, and lacquer-like deposits when in contact with oxygen, and these deposits have the effect of causing sluggish operation, excessive wear, and a reduction in clearances.

Experiencing high temperatures for a prolonged period of time accelerates the oxidation process in greases.

Aspects of high temperature

Oils are more susceptible to damage from high temperatures than greases are. Convection is not an effective method of dissipating heat from grease like it is in circulating oil. Because excessive temperatures cannot dissipate heat, they cause grease to harden and cause carbonization.

The consistency of grease determines its effectiveness as a lubricant. During high temperatures, grease softens and bleeds, causing it to flow away from needed areas. If the temperature of grease exceeds 177°C, mineral oil in the grease may flash, burn, or evaporate.

Impact of low temperatures

Grease becomes hard when the temperature is lowered enough to become viscous. Due to torque limitations and power requirements, pumpability suffers and machinery operation is difficult.

The low-temperature limit of grease is based on the pour point of the base oil.